Forest to Home

Sustainable Furnitury

Our story

With Mule Wood being located in Northern New Mexico there is a unique opportunity to provide beautiful sustainable wood products. Working in conjunction with the forest service we provide a service to both the forest and the consumer. Identifying and removing invasive species, clearing fuel wood for fire mitigation, as well as trail and road clearing. Then putting that wood to work as end user wood products.

Adam Mueller

Mule Wood really started with Mueller Woodworking, my father’s carpentry shop in central Pennsylvania. Growing up around woodworking and heating with wood gave me a complete picture from the woods to the end product, though I didn’t take advantage of it for many years. I moved into the IT industry, then started and ran Mueller Networks a low voltage wiring company for many years. During that time, I also acquired many other skills such as metal fabrication and welding. After deciding I wanted something different, I went into healthcare and became a Paramedic. That was also when my wife and I decided to move from Georgia to the land of enchantment. I currently maintain a Paramedic license in New Mexico and cover shifts. Seeing the issues plaguing healthcare I decided I wanted to draw on my previous experiences and build things. With all of the tools and knowledge from metal to wood to wiring I plan to create unique and timeless items for people to enjoy.

Tree mitigation clearing cleanup

[Talk about tree trimming, clearing, cleanup services around Santa Fe. OR about working with local arborists. Showcase being able to make products from that tree for the end user, explain drying times, wood movement, ]

Images of trees with labels

Images of various tree clearing, felling etc

The Wood

[Explain hardwoods, softwoods, talk about reclaimed lumber (disadvantages and advantages of pallet/old siding/barnwood), more about drying time, wood movement, processing technique, grain direction, splinters, cracking,etc]

Images of different woods, examples of cracking bowing, cupping

The Build

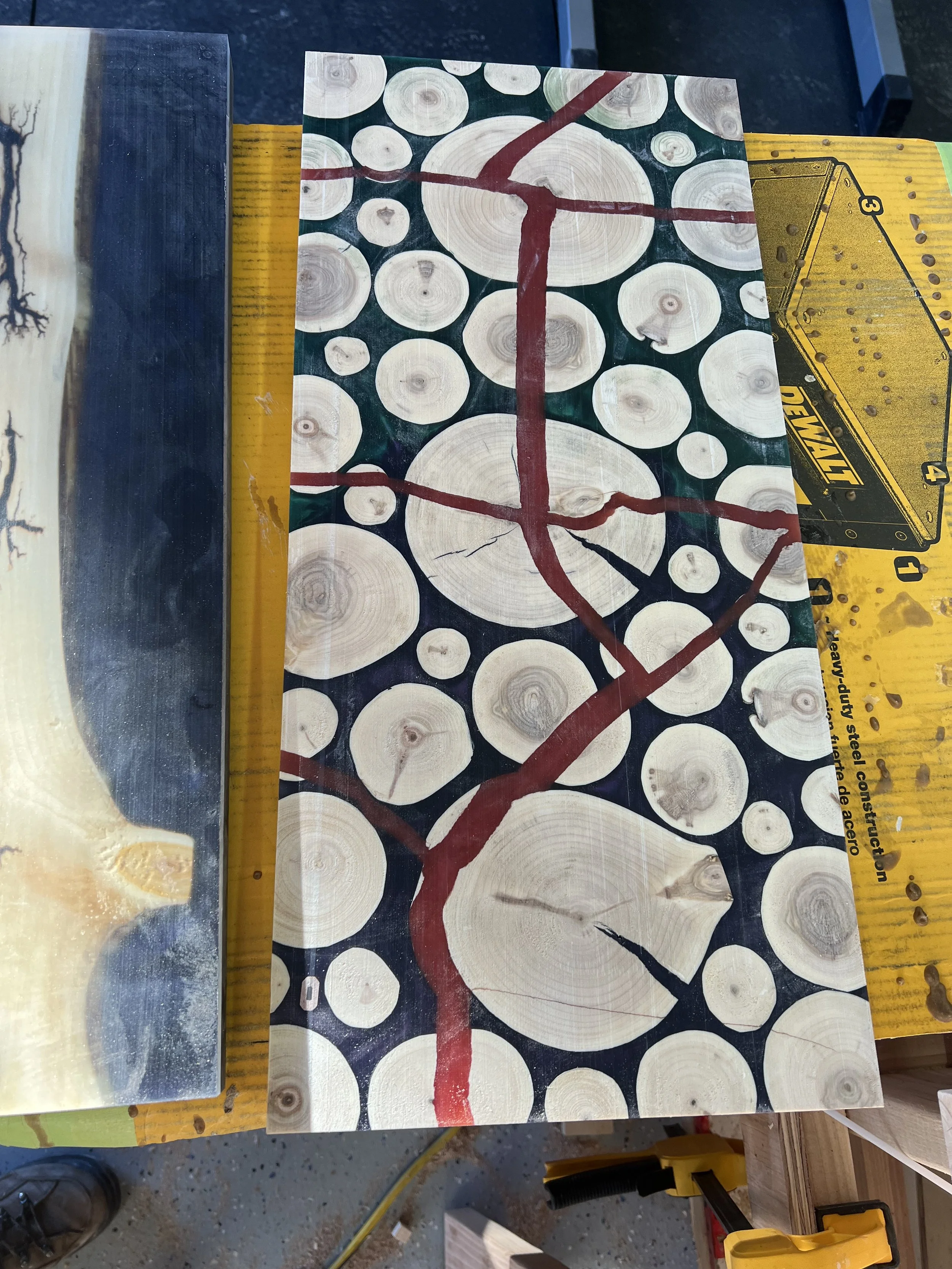

[Explain build techniques(rustic to fine furniture), joinery, pros/ cons, touch on epoxy, metal and wood together, factual burning]

One of the most interesting and complex things about furniture and wood working is the build. There can be two functionally identical pieces of furniture that have completely different build qualities. Furniture builders will look at a table and see the slight variations in build quality that the average person would never notice. These differences may be important to one person but mean nothing to another. As an extreme example a table can be hand crafted with no metal hardware, intricate hand cut inlay out of exotic woods or it can be screwed together with common lumber and use gas pipe (commonly known as black pipe) for legs. They both serve the same function, as a surface to place things on. There is even a trend for this “industrial” style using common industrial parts and leaving them exposed. One style is not any better or worse than the other if they are both constructed to the same strength.

There is however a significant difference in the time and effort required to produce the two products. There are some other factors that differentiate the two also, usually longevity, depending on the exact construction. It is interesting to hear people talk about things like veneer or plywood with disdain yet much of what is purchased is veneer over particle board. All of our products are made from solid wood.

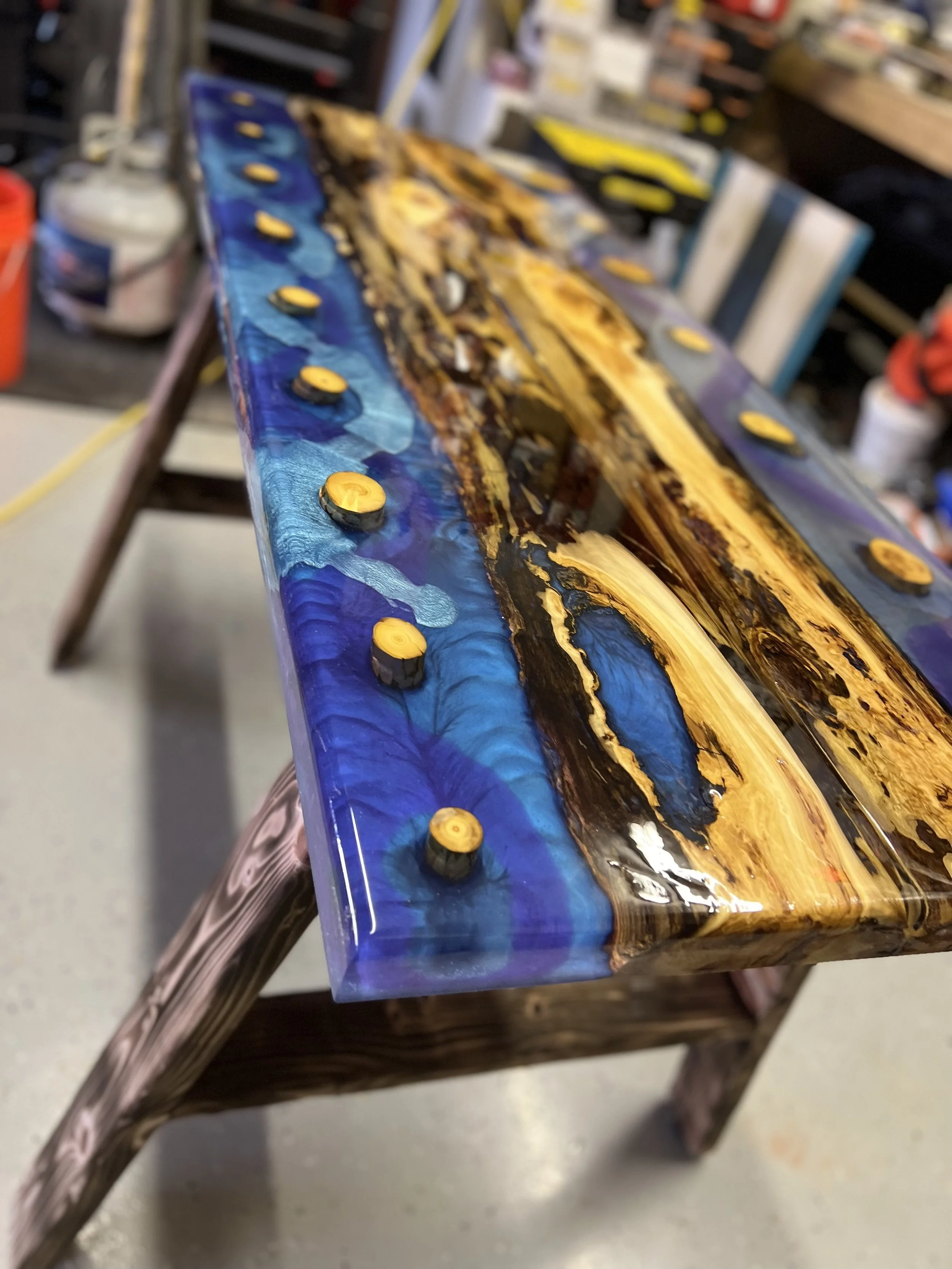

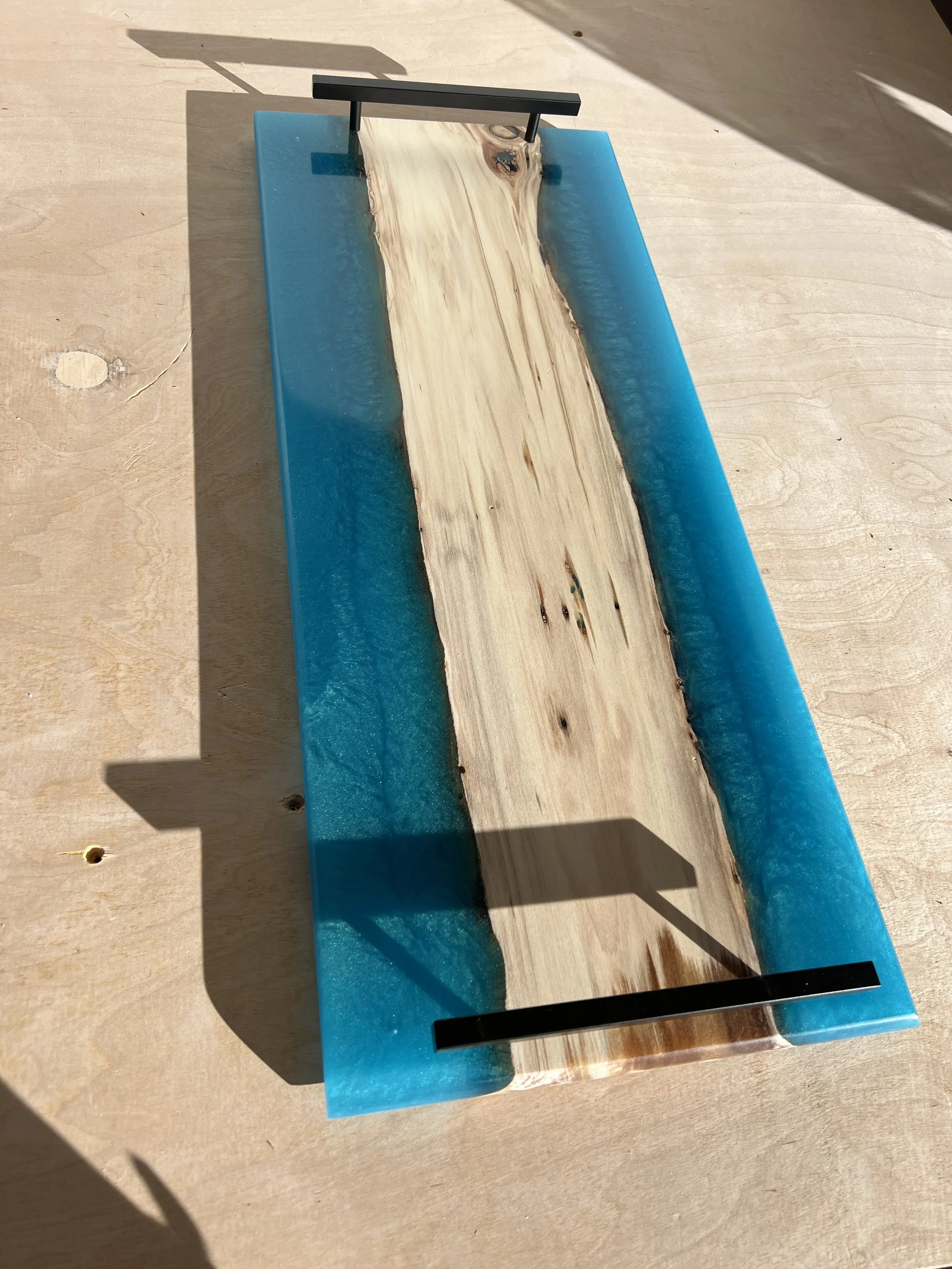

There is also a trend for epoxy with “live” edges in wood furniture. To clarify the term live edge is only that the edge of board or slab cut from a tree has not been cut off during the milling process. Until recently this was just waste wood usually being chipped and made into particle board or MDF. When a tree is milled there are multiple ways it can be cut. These different cuts determine the final price of the lumber but also its properties.

Types of milling cuts. Plain Sawn, Quarter Sawn, and Rift Sawn.

The Finish

[Explain finish techniques, more on epoxy finish coats, pros cons other finishes etc. ]

Images of joinery

Images of finishes

THE WOOD’s

Northern New Mexico’s most common trees are Douglas Fir, Engelmann Spruce, Pinion Pine, Ponderosa Pine, Quaking aspen, Subalpine Fir, and the White Fir.

Norther New Mexico is a high desert and mountainous region which facilitates the growth of mostly coniferous trees. Coniferous trees do not drop their leaves in the winter and are considered a softwood while deciduous trees drop their leaves in winter and are considered hardwoods.

Within coniferous trees common types are Fir, Pine, and Spruce these generally have similar characteristics for building, with straight grains, good workability and generally light weight. They all have needle like leaves but with distinctions, spruce needles are attached singularly to the twig and are sharp while fir needles are also attached singularly they are flat flexible and not sharp. Pine needles are attached in clusters to the twig with different amounts of needles per cluster determining species.

The hardness of wood is rated on the Janka hardness scale which is determined by the PSI required to push a steel ball halfway into a wood plank. So while Aspen is considered a hardwood because it is a deciduous tree it’s Janka hardness number is ~350f while Douglas fir a softwood has a hardness rating of 620-710f.

So while aspen is a hardwood it is actually very soft. Another unique characteristic of aspen is that it does not splinter. making with useful for building things such as toys and items that will be handled frequently.

Invasive species Siberian Elm, Russian Olive, Tree of Heaven [Same as above, attributes, identification, reason to remove them]